And features that make your P2P business better.

Table of contents:

– What is the point to point distribution model?

– Advantages of P2P distribution

– Disadvantages of P2P distribution

– What deliveries are suited to point to point distribution?

– How automation supports point-to-point distribution

After our discussion about the hub and spoke model, let’s take a look at a very different one: the point to point distribution model.

It’s fair to say they’re polar opposites in terms of how they function. That’s because they serve different kinds of deliveries. So, what is the point to point model, who should use it, and how can you make the most of it?

First, let’s run through a brief explainer: how does the model work?

What is the point to point distribution model?

A point to point distribution model can work in a couple of different ways. The most obvious is to directly connect two different locations without any service interruptions (like pick up or drop off). Your driver’s route is uninterrupted from point A to point B.

The second is where the pickup and delivery are serviced by the same driver but aren’t necessarily direct. The driver might complete pickups in the morning and deliveries in the afternoon. They could even do a pickup in the afternoon and complete the delivery the following day. The defining feature is that the freight is only handled by a single driver and it doesn’t return to a central hub or depot.

So a vehicle can be loaded in Moorebank, Sydney, then travel to Marrickville to be unloaded and delivered.

You can see how this differs strongly from the hub and spoke model, where each location is connected only to a central hub, which then combines deliveries together into a larger vehicle eventually headed to the same location.

Advantages of P2P distribution

There are two main advantages of the point to point distribution model over the hub and spoke model: faster travel times and lowered impact of delays. Let’s look closer.

Faster travel times. Using the point to point model means making a continuous journey to your drop off point. Your drivers won’t be stopping, changing directions, or accommodating other deliveries at the same time.

Obviously, the time from loading to final delivery of goods is almost always going to be faster when there’s no stops in the middle.

Delays have a lower impact. With this distribution model, delays only affect a single delivery. As opposed to a hub and spoke model where a delay at the central hub can have an impact on large numbers of deliveries at once, which are all waiting to leave in the same vehicle.

Because each vehicle is operating independently in a point to point distribution model, they’re better able to resolve any issues quickly. Therefore, the model is less prone to delays between locations.

Disadvantages of P2P distribution

There are two main drawbacks to the point to point distribution model: lower efficiency and higher costs.

It may be fast but it’s not as efficient. And if you run a transport business, then you know how fundamental efficiency is to a financially successful business. The point to point distribution model requires more of your drivers to be on the road at once.

If they’re all travelling in similar directions, you could consider sharing the loads in a Less Than Truckload (LTL) set-up, using a hub and spoke model.

The other factor to consider is that with point to point deliveries, each ‘point’ needs to be set up with procedures and facilities to process deliveries individually from many sources. This is where automated

It’s more expensive. When you have more drivers on the road at once, you usually pay for more: wages, fuel, route planning, vehicle insurance and maintenance.

That’s adding up now, isn’t it?

What deliveries are suited to point to point distribution?

Even with these drawbacks, in the right context the point to point distribution model is still the best choice. So when should you use it?

Courier businesses are an excellent example of successful (and necessary) point to point distribution models. Couriers are known for delivering important goods quickly, aren’t they?

Their pricing takes into account the required staffing and fleet structure to deliver fast moving consumer goods so quickly. Everybody recognises the role they play in our transport system, and the logistics landscape would look very different without them.

How automation supports point-to-point distribution

Clearly, point to point distribution models are a necessary part of our national transport system. Happily, if you run a courier business, then a full featured transport management software will give you tools to smooth and speed up these urgent, time sensitive operations.

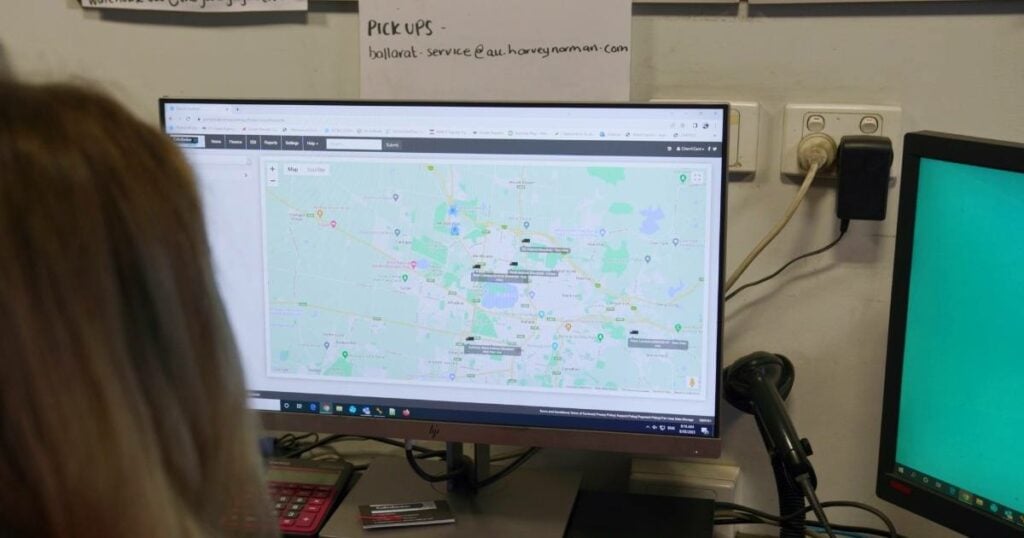

Automated smart dispatch. When seconds matter, the ultimate level of speed is achieved with fully automated dispatch workflows. Get the data to your drivers and the vehicle on the road immediately.

Multi carrier support. Use an all-in-one platform providing freight managers, brokers and despatch warehouses with access to a wide range of leading carriers. Get unparalleled reach.

Route planning optimisation. Route optimisation saves time, lowers costs and gets freight where it needs to be faster. This part’s pretty simple: more efficient routes mean higher profits.

Still got questions?

We hope this cleared a few things up for you between the hub and spoke and point to point distribution models. If you still have any questions about how it relates to your business or how you can improve efficiency, just drop us a line. Our friendly team is here to help.

And if you know someone else who will benefit, please share this guide with them