Table of Contents

Today’s technology allows business to collect more data than ever before. Supply chains are especially stacked with information. Many transportation and logistics companies use sensors, GPS trackers, transport dashboards and Internet of Things (IoT) devices to generate mountains of information. In fact, the number of companies adopting IoT for real-time tracking rose to 60% while those using AI for predictive analytics went up to 45% this year.

By expectation, this should give business unprecedented control and understanding in their operations. Yet many companies still struggle to make the best decisions out of the piling data technology churns out for them every second.

This paradox is known as the visibility gap—the state when companies are data-rich but not insight-rich. Despite huge investments in digital supply chain tech, visibility gaps are still persistent.

Understanding the Visibility Gap: What the Numbers Are Saying

In the US, where supply chains are sprawling, complex, and often caters to a global scope, the gap is even more pronounced.

Current state of visibility

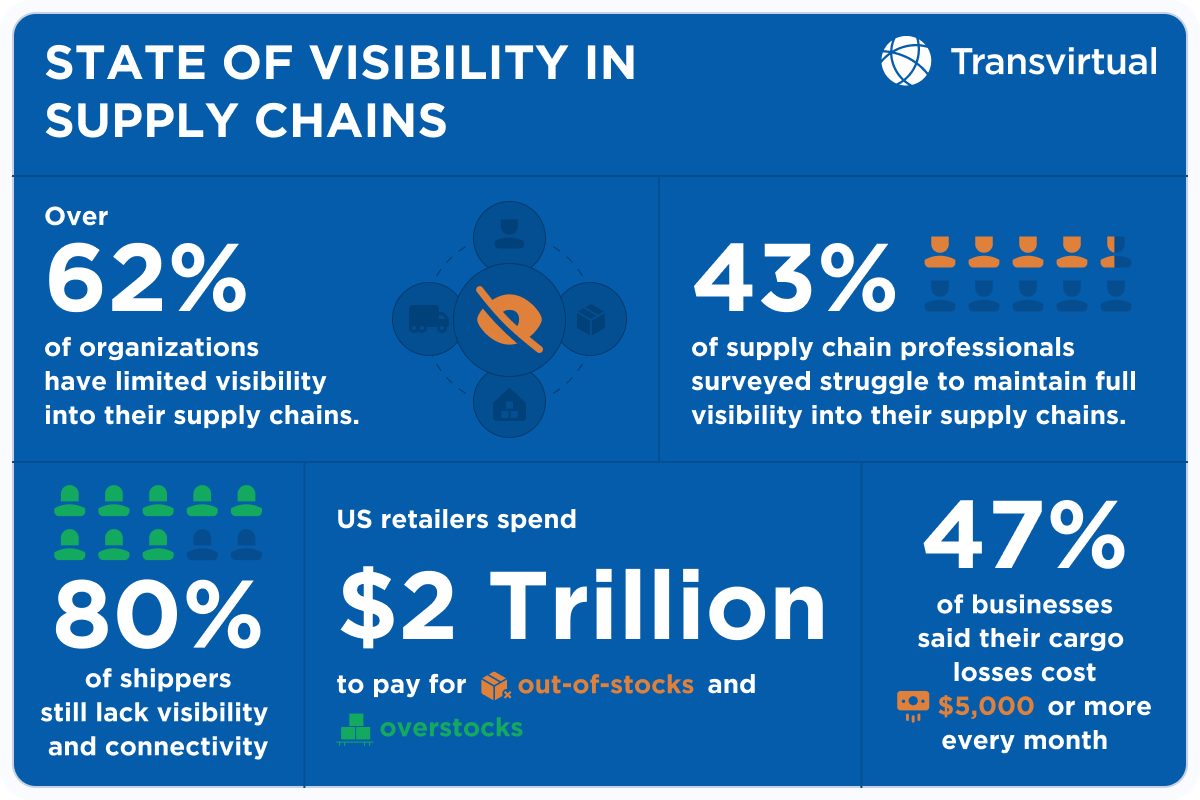

Over 62% of organizations have limited visibility into their supply chains.

Nearly half (43%) of supply chain professionals surveyed struggle to maintain full visibility into their supply chains.

A survey by Tive revealed that 45% of supply chain experts reported having visibility into less than half of their total shipments.

87% of businesses reported that they get the least visibility when the goods are in transit.

The demand and desire for visibility

Tive’s survey also showed that 80% of shippers still lack visibility and connectivity. The respondents shared that data sharing and collaboration are crucial to their operations.

77% of businesses stated that the need for real-time visibility is a must-have feature.

74% of supply chain professionals want to keep or raise their spending on real-time visibility solutions.

Consequences and costs of the gap

The lack of visibility translates directly into massive financial losses and operational inefficiencies

At the height of the pandemic in 2020, the disruptions majorly compounded by visibility gaps led to a loss amounting to $4 trillion.

US retailers spend $2 trillion to compensate for out-of-stocks and overstocks.

47% of businesses said their cargo losses cost $5,000 or more every month.

Damage and Security

59% of real-time visibility investments are due to security concerns.

Unfortunately, 45% of companies only find out about cargo damage post-delivery, when it’s too late to do anything.

Operational waste

Warehouses consume up to 6,500 hours every year just to do cycle counts and stock checking.

Customers take 24 minutes on average to resolve stock discrepancies.

The Illusion of Visibility

Supply chain visibility is the means of tracking and monitoring products throughout their lifecycle. This includes raw materials, in-transit goods, warehouse inventories, and final deliveries. Simply put, it’s about knowing where your products are, what condition they’re in, and how efficiently they’re moving through the system.

Modern visibility relies on tech to coordinate shipments, enable real-time tracking, connect multiple partners, and turn data into predictive insights. This empowers logistics teams to make faster and wiser decisions.

However, access to data doesn’t guarantee better understanding of them. Instead, it creates a false sense of visibility. This is where the so-called “illusion of visibility” comes from. The dozens of KPI, efficient live map, and tracking numbers is nothing if you still miss what’s happening.

This is why there is a huge difference between data visibility and insight-rich visibility. Data visibility answers the “what”, while insight-rich visibility answers the “why” and “how.”

Data visibility answers the “what”, while insight-rich visibility answers the “why” and “how.”

Why More Data Doesn’t Equal Better Decisions

American supply chains operate at an intense pace. With just-in-time manufacturing, global sourcing, and rapid e-commerce fulfilment cycles, teams are flooded with information, from sensors, scanners, TMS platforms, and IoT devices. Instead of improving control, this paralyzes decision-making. Analysts spend hours sifting through conflicting data instead of acting on it. Managers lose sight of what matters most: responding intelligently to disruptions and opportunities.

Data overload or analysis paralysis has become one of the biggest barriers to meaningful supply chain visibility. US companies are drowning in data. The problem lies in how that data is managed, interpreted, and applied.

Major US retailers use predictive analytics to move from reaction to anticipation. Instead of logging late shipments, their systems analyze traffic patterns, weather data, and carrier performance to predict delays before they happen. This allows procurement teams to adjust sourcing decisions, warehouse managers to rebalance inventory, and customer service teams to set realistic expectations in real time.

The lesson is clear: data is only as powerful as the insight it delivers. Visibility doesn’t mean staring at hundreds of metrics. It means seeing the right ones at the right time and understanding what they mean for your business.

Because in the end, visibility isn’t about seeing more. It’s about seeing better.

What’s Causing the Visibility Gap

Despite record levels of investment in tracking tools and analytics platforms, many US supply chains remain disconnected at the operational level, making it difficult to turn data into actionable insights.

A Medium compilation of 50 U.S. data governance case studies found that most organizations fail not because of insufficient data, but because of unstructured and unaligned data strategies.

The problem isn’t that there’s too little data. It’s that it’s spread across too many places, in too many forms. Let’s break down the key causes behind the visibility gap.

Data silos

While supply chains run on collaboration, data often doesn’t. Transportation management systems, warehouse platforms, and carrier portals all collect valuable information, yet they rarely “talk” to each other.

This fragmentation creates data silos, where critical insights are trapped inside separate systems or departments. Without integration, teams often only see a part of the puzzle, not the whole picture. Working with partial information makes it hard to detect trends or anticipate issues.

Inconsistent Formats

Even when data is available, it often arrives in different formats like spreadsheets, PDFs, EDI feeds, API outputs, and from vendors using varied standards.

This lack of standardization makes it difficult to combine or interpret information in real time.

For instance, a carrier might report shipment statuses in time zones or codes that differ from a warehouse system. As a result, logistics managers spend more time reconciling data than acting on it.

Limited Context

Visibility isn’t just knowing where things are. It’s knowing why they’re there and what’s next. Yet most systems lack context. GPS data shows location but doesn’t explain delays. Temperature sensors detect changes but don’t correlate them with risk thresholds or delivery windows.

Without contextual analytics, teams are left reacting to surface-level data instead of addressing root causes.

Technology Sprawl

Many organizations have adopted multiple tools, each promising better visibility. But the result is often technology sprawl, where dozens of platforms overlap, creating complexity instead of clarity.

Using several visibility or data systems leads to duplicated effort, inconsistent metrics, and rising IT costs. True visibility depends not on more tools, but on better orchestration between them.

Human Factor

Even the best data is useless if people can’t interpret it effectively. Logistics teams today are overwhelmed by dashboards, alerts, and KPIs, many of which lack prioritization or context.

This can result in supply chain managers and leaders struggling to identify which alerts require action. This cognitive overload leads to slower responses and missed opportunities.

How to Bridge the Visibility Gap

It’s clear that bridging the gap is about connecting people, systems, and data into one cohesive network. Many logistics leaders are realizing that achieving true visibility requires a strategic blend of integration, automation, and human understanding.

Here’s how to make it happen.

Integration: Unify Data Across Supply Chains

The first and most critical step is integration. A supply chain cannot be visible if its data lives in silos. Transportation, warehousing, and order management systems must work in unison, not as separate entities.

Platforms that consolidate data streams, such as modern Transportation Management Systems (TMS), create a single source of truth.

Centralizing transport, warehouse, and order data, logistics teams enables businesses to detect patterns, predict disruptions, and coordinate responses faster. Integration doesn’t just improve visibility, but also strengthens collaboration across suppliers, carriers, and customers.

Automation: Eliminate Manual Data Handling

Manual data entry remains one of the biggest sources of error and inefficiency. Every spreadsheet, email update, or manual check-in slows down decision-making and increases the risk of misinformation.

Automation also means fewer routine tasks for human teams, allowing them to focus on higher-value analysis and proactive planning. Tools that automate document exchange, invoicing, and compliance reporting not only reduce human error but also create an uninterrupted data flow across the network.

Accuracy and Consistency: Focus on Data Quality

Quality beats quantity when it comes to visibility. Inaccurate or delayed data undermines trust and decision-making.

To fix this, businesses need to establish clear data governance standards, ensuring accuracy, timeliness, and consistency across every partner and platform.

That might mean adopting universal product identifiers (such as GS1 standards) or enforcing real-time updates through APIs rather than manual uploads.

When data quality is high, visibility becomes reliable. And that reliability builds confidence across the entire supply chain.

Data to Insights: Invest in Analytics Tools

Investing in analytics and AI-driven tools can transform raw data into actionable insights. These platforms can identify patterns, predict disruptions, and recommend optimized routes or carrier choices.

For example, predictive analytics can flag shipments at risk of delay or highlight recurring inefficiencies in a certain lane. By layering context over data, analytics helps teams move from reacting to anticipating.

Team Empowerment: Train Team, Not Platforms

Technology alone won’t close the gap. Even with advanced systems, data is only as valuable as the team interpreting it. Training employees to read dashboards, understand KPIs, and connect insights to actions is critical.

Organizations that invest in data literacy programs see faster decision-making and better collaboration between logistics, finance, and customer service teams. When users know how to interpret data, not just view it, they turn visibility into value.

Turn Visibility into Value

True visibility isn’t about collecting endless data streams. It’s about creating clarity that drives smarter, faster decisions. The real question for today’s US supply chain leaders is: Is your organization insight-rich or just data-rich?

As the supply chain landscape continues to evolve, those who can bridge the visibility gap will be better positioned to navigate disruptions and drive business success.

For companies looking to enhance their supply chain visibility, solutions like Transvirtual offer integrated platforms that provide real-time insights and analytics, helping businesses make informed decisions and improve operational efficiency.

Frequently Asked Questions

Here are the reasons why there are visibility gaps in supply chains:

Data silos between departments or systems

Inconsistent formats that make data hard to compare

Technology sprawl or having too many disconnected tools

Poor data quality or outdated information

Limited context or knowing what’s happening but not why

To close the visibility gaps in supply chains, here’s what businesses can do:

Integrate systems across transport, warehouse, and order data

Automate manual processes where possible

Focus on data quality such as accuracy, timeliness, and consistency

Invest in analytics tools that turn raw data into insights

Train teams to interpret and act on data, not just view it

Transvirtual provides a unified logistics management platform that integrates delivery, tracking, and performance data in one place. This helps businesses move beyond fragmented visibility, enabling faster, data-informed decisions that improve service and profitability.